November 2021

Help us build a chemical-free alternative to save your bees from Varroa!

We have developed a unique insulated queen-excluder design which we are producing in a small batch of 50 units. These are made out of food-grade silicone and will be available from mid December.

This queen-excluder is one part of our complete chemical-free automated Varroa mite treatment system, however one of our initial trialists suggested this would be useful as a standalone product, so we would like to test it by itself with a wide range of beekeepers. This is where we need your help.

We aim to test whether good honey yield is achievable with it on the hive all year, while potentially benefiting the colony by reducing its caloric requirements to maintain optimum brood temperature.

If you would like to participate in the queen-excluder trial or know more about it, please let us know via email feedback@hivesite.co. Also feel free to pass this on to any other innovative beekeepers you may know. We are looking for beekeepers both big and small, preferably based in New Zealand.

Feedback from Apiculture Conference

At Apiculture in June we connected with the beekeeping industry and researchers to both promote our work and learn more about the latest developments in beekeeping.

Overall we had very positive feedback and some great suggestions in terms of the design and considerations from a variety of beekeepers and stakeholders. Our target pricing (ballpark NZD$200 per hive) was generally acceptable by customers as well.

Current Development status and Trial

We have been busy developing our improved prototype and have learned a lot about what works and where we need to improve so that we deliver a robust solution over the long run. We now have 12 months of real-world trial data that is showing promising results.

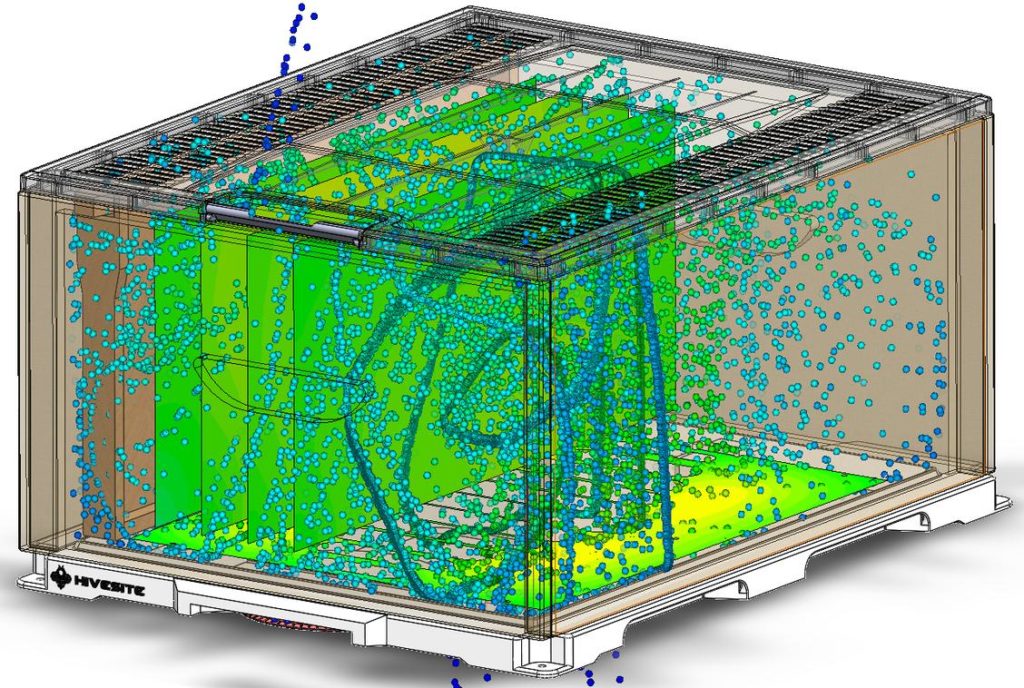

In lab conditions we showed treatment is effective when applied at a narrow temperature range for a specific time in order to kill off mites on a single frame, without harming the colony. It also needs to be applied uniformly, as well as frequently enough to keep numbers down, which are both complex in real world conditions. We are also using simulations (e.g. pictured below) to help refine the design to maximize uniform heat distribution.

We are working hard to translate this technology into an automated easy to use system and aim to have our first units available in 2022.

Sprout Accelerator

We were one of 12 startups lucky enough to spend the last 3 months participating in the ag-tech startup accelerator, Sprout.

It was fantastic to be a part of this cohort and receive mentorship from an amazing team of experts. We learned a lot about early stage business development and are more prepared than ever to bring this product to reality and help all beekeepers deal with the Varroa problem.